|

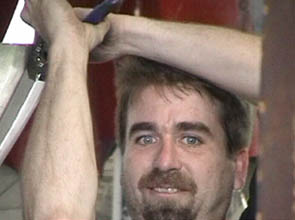

The final stages of fabrication included a lot of fitting and trimming. Over the joints of the segments of the perforated aluminum strips were placed aluminum trim pieces. Since everything was not only on a curve, on a spherical surface, but also tapered, every piece had to be fit and trimmed individually. Mark is trimming one of the aluminum trim pieces on a porta-band saw clamped in a large vise. John is carrying the artist's conception of this globe - he had to design and dimension all aspects of the actual construction.

|

|

|

Another of John's current projects was sitting in the shop - a church steeple with outlines of the stained glass windows. All this is constructed from aluminum bar stock, welded to created a forced perspective of the rising steeple. At right is one of the jigs he made up for the welding of the pieces. One of John's current specialties is the welding of aluminum, but Mark considers him to be somewhat of a magician with all kinds of metal work. One of the favorite stories about John, an avid motorcylcist, is his welding of a broken motorcycle chain way out in the woods somewhere. Using the arc obtained from the battery and a couple of sharp pieces of metal, he spot-welded the chain together and rode back in. From such stories, legends are made.

|

We took a break for some fun and games, and one of John's tricks was the suspension of a screwdriver on an air jet from the compressor. It surprised me, but he said any round-topped screwdriver would work. I had taken out some liquid nitrogen because Mark thought John would enjoy that. So we spent some time freezing things and playing with the nitrogen. |

|

|

|

Index

2002 |